Temperature and time are examples of steam sterilization parameters. The concentration of ethylene oxide and time are selected for EO sterilization.

Chemical Indicators are used to be specific that packs are having entirely coated, and adequately penetrated with steam. You will find typical chemical indicators, and There may be chemical indicator tape.

Chemical indicators are useful for soil tests applications, swimming pool h2o tests reasons, and identification functions of assorted chemicals.

Sterilization indicators present whether or not the situations in a very steam autoclave system have been sufficient to obtain a certain point out of microbial inactivation.

That’s The best Section of everything. Just contact us here and we will let you with all the data you need. We offer the goods also and provides you Absolutely free Technological Aid for installation, setup, and use of these for life.

AAMI identifies 6 types of chemical indicators, with Each and every variety owning distinct effectiveness specs that must be achieved. Learn more about the types of chemical indicators Utilized in Health care.

In addition it gives samples of applications and STERIS Daily life Sciences products and solutions available for Every kind. Utilize it to aid choose the right chemical indicator for checking unique sterilization processes.

Our vision can be a earth where our impressive items, expert services, and digital offerings aid make alternatives for men and women globally as well as a sustainable long term for generations to come.

Delphinium Petals: The anthocyanin delphinidin adjustments from bluish-purple in an acidic solution to violet-blue in a very standard Answer.

An indicator could possibly be accustomed to establish the endpoint of a titration. This will entail the appearance or disappearance of the shade.

They alter their assets like coloration in acid or base Resolution to expose the different properties in the alternatives.

How are chemical indicators useful for sterilization? Chemical indicators need to be Employed in all types of sterilization processes which includes: steam, hydrogen peroxide, and ethylene oxide.

Qualification tests verifies the sterilizer’s performance before it's employed. Qualification tests needs to be done immediately after set up or relocation and soon after sterilizer malfunctions, sterilization failures, read more or major repairs.

They may be utilized for steam, ethylene oxide and hydrogen peroxide sterilization procedures and should be used Any time a precise dosimetry of such chemicals or radiation is important.

Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Michael J. Fox Then & Now!

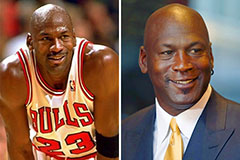

Michael J. Fox Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now!